Altech

Metal Detection Systems

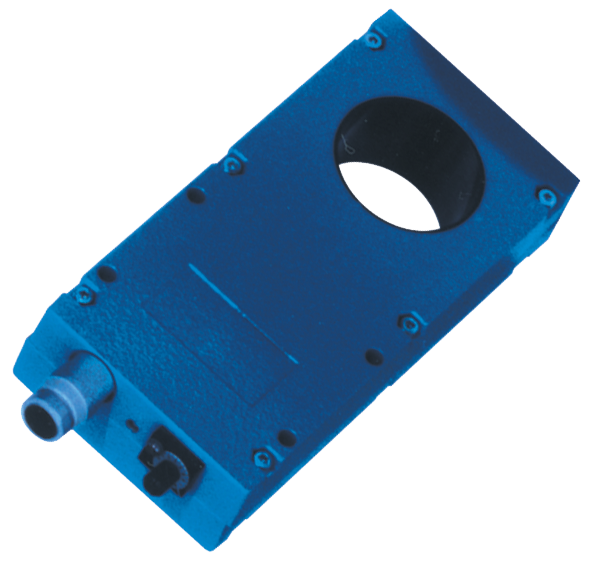

They are Static Type Ring Sensors and their advantage is the ability to detect non-moving static objects. If metal is within its detecting range it generates a permanent output signal. Only when the metal object is removed the signal is deactivated. Due to the working principle the sensitivity is lower than on dynamic Ring Sensors.

Applications include Freefall applications to detect the presence of metal objects, count metal parts or ejection control in punching/ stamping applications, wire breakage and avoid unwanted metal objects in grinding operations. They are used for larger metal objects.

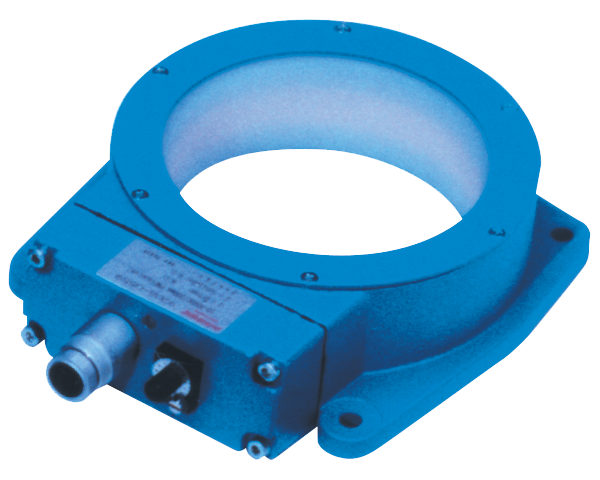

They are Dynamic Type Ring Sensors and generate a short signal pulse when metal is detected within its detecting range. Only moving metal objects can be detected. Sensitivity on dynamic Ring sensors is higher than on static type sensors. Therefore smaller objects can be detected.

Applications include Freefall applications to detect the presence of metal objects, count metal parts or ejection control in punching/ stamping applications, wire breakage and avoid unwanted metal objects in grinding operations. They are used for much smaller metal objects than the normal sensitivity Ring sensors.

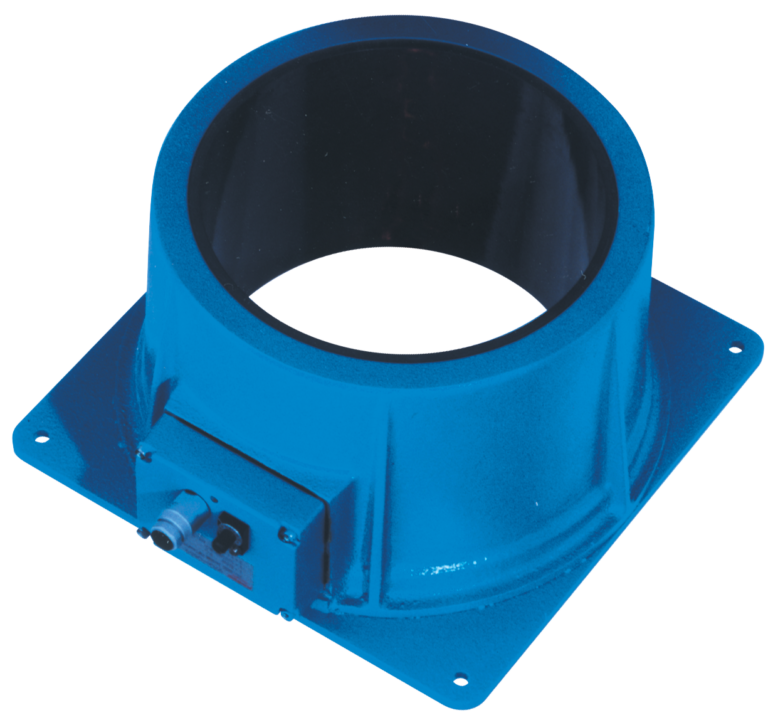

Ultra High Sensitivity Ring Sensors work different than standard metal sensors. Their system is based on 3 coils. This allows the end user to analyze signals precisely. It is possible to differentiate different targets and draw conclusions on their origin.

Applications include all of the above, but Ultra High Sensitivity Ring Sensors are used primarily for the detection of very small particles in bulk material (Pharmaceutical products, Food and animal feed, granulated polymer materials, etc…).

Please feel free to contact us – We are ready to help with any application. Call us at (208) 322-2425